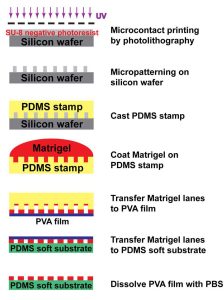

Engineered Micropatterned Platform

The Crone Lab has developed micropatterned platform to influence the maturation of immature myocytes differentiated from stem cells which have also been adapted for use with both cardiac and skeletal muscle cells. We have developed a technology platform that allows the production of a range of micropatterns on substrates of varying stiffness. In contrast to standard two-dimensional cultures where muscle cells form cell-cell junctions in all directions, we have shown that immature muscle cells patterned in lanes repeatability form extremely polarized structures which produce synchronous contraction, highly enhanced sarcomere organization, and anisotropic conduction.

Surface Modification of Shape Memory Alloys

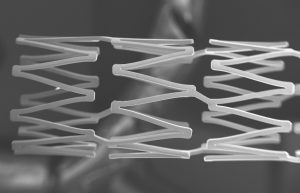

Shape memory alloys are a unique class of materials that undergo a reversible phase transformation that allow the material to display dramatic, recoverable, stress-induced and temperature-induced deformations. Nickel titanium (NiTi) is one such shape memory alloy used in a range of industries for products such as biomedical devices and aerospace components. The most familiar uses of NiTi are arterial stents and dental arch wires used in orthodontic braces. The austenite-martensite phase transformation that occurs in shape memory alloys with changes in temperature or the applied stress is responsible for the unique thermomechanical properties of this material. Our research has focused on developing a better fundamental understanding of these alloys through investigation of its macroscopic behavior and phase transformation mechanisms at the microscopic level.

Our research with surface modification of NiTi established plasma source ion implantation with oxygen as a technique to create a functionally graded surface. This approach improves wear, corrosion, and biocompatibility while retaining mechanical properties of the bulk material for medical device applications with complex geometries (stents) and porous surfaces (orthopedic implants). Immersion in the plasma for surface modification produces a robust, conformal, functionally graded surface with superior biocompatibility which does not compromise the material’s shape memory and pseudoelastic properties.

Fracture of Shape Memory Alloys

The Crone Lab has addressed several key questions concerning the fracture behavior of NiTi and CuAlNi. NiTi is the shape memory alloy (SMA) most frequently used commercially. However, due to the cost of raw materials and difficulty of processing, applications using NiTi are limited due to cost. Another SMA that has drawn interest is CuAlNi given the low cost of raw materials and ease of processing. However, CuAlNi has not been used due to the tendancy of this alloy to fracture intergranuarlly at a low number of thermal or mechanical cycles. In order to understand the fracture mechanisms of shape memory alloys, experiments on notched polycrystalline and single crystal samples were tested. These experiments have assisted in developing experimentally based models that delineate the mechanisms influencing fracture in NiTi and Cu-based shape memory alloys.

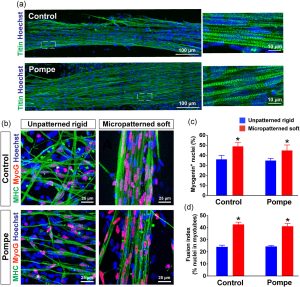

Skeletal Muscle Constructs

While in vitro culture systems have limitations, they also have powerful advantages that enable controlled experimental investigation. Our culture platform has been adapted and optimized to study skeletal muscle where we have shown that progenitor cells remodeled their myofilament structure and formed elongated, multi-nucleated myotubes in response to topographical cues of the micropattern. Both micropattern width and substrate stiffness can be used to synergistically promote fusion and differentiation of stem cell derived myocytes that then exhibit spontaneous coordinated contractions. We also developed bundle-like myotubes using patient-derived induced pluripotent stem cell (iPSC) with Pompe disease which exhibited an enhanced disease phenotype with abnormal lysosome accumulations. This research was conducted in collaboration with Prof. Masatoshi Suzuki in the School of Veterinary Medicine is investigating modelling of the muscle-tendon junction to study myotendinous junction development and repair.

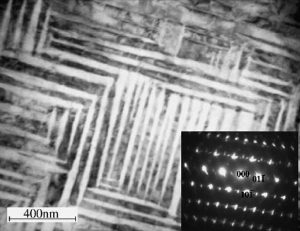

Nanostructured Shape Memory Alloys

Nanoscale materials have attracted strong interest because of the novel material properties that become possible when surface effects and grain boundary behavior play a larger role in the overall mechanical behavior of the material. Shape memory alloys also continue to be explored for more dramatic superelastic behavior. It has been shown that refinement to the microscale is correlated with enhancement of the properties in copper-based, iron-based alloys, and nickel-titanium shape memory alloys. Taking this a step further, the Crone Lab has explored the properties that result from combining the effects of nanostructures and shape memory. At the onset of this research there were several open questions fundamental to the understanding of shape memory behavior, furthermore shape memory behavior in the nanometer regime had not yet been explored. Also, it was not known whether the transformation microstructures observed in single crystals and large grained materials would persist to nano-sized grains, or whether other transformation microstructures occur at these size scales. In our research we were able to create nanostructured shape memory alloys in bulk and particle form; explore the effect of grain constraint on the nucleation and propagation of phase transformation; investigate scaling effects on shape memory behavior; and improve fatigue life, workability, and superelastic behavior through grain refinement.

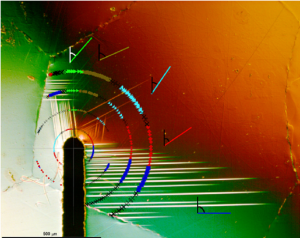

Quantification of Sarcomere Organization

The Scanning Gradient Fourier Transform (SGFT) method provides a tool for quantifying sarcomere organization and alignment. The incorporates gradient analysis along with fast Fourier transforms for analysis of high resolution images of sarcomere within individual cells or populations of cells.

Mechanics of Responsive Hydrogels

The Crone Lab has studied responsive polymeric hydrogels to facilitate the use of hydrogels as autonomous actuators in microfluidic devices. Through interdisciplinary collaborative research, we have provided comprehensive analysis of these materials combining experiments with theoretical modelling and simulation. Fundamental understanding of the mechanics of responsive hydrogels has provided the foundation for the development and application of hydrogel-enabled microfluidic devices for microdispensing, cell-based assays, and infusion of protein therapeutics.

New Biomaterials and Device Designs for Aneurism Occlusion

Biomedical devices such as stents and vascular grafts are often coated with various materials to prevent problems such as clotting around the device. Typically, the base material provides the mechanical properties desired while the coating provides biocompatibility. An alternative approach is to make the base material biocompatible. As an example, one of our research projects focused on the development of polyurethane based polymers with hyaluronic acid and dermatan sulfate that possess mechanical properties similar to the surrounding biological materials. Matching the mechanical properties of the device to the surrounding structures, especially the stiffness, results in better performance. We created two new medical device designs (coil-in-shell and gel-in-shell devices) for aneurism occlusion which were studied acutely in swine and long term in canines. Initial occlusion of sidewall aneurysms ranged from 71% to 100%, which was stable with no recurrence at 6 or 12 weeks. Beyond the highly successful in vitro studies, histological analysis conducted after 12 weeks showed that the polyurethane–hyaluronic acid copolymers promoted robust tissue healing at the aneurysm neck with no significant inflammatory response. This research, which also resulted in three patents, was done in collaboration with Prof. Kristyn Masters’ Group and neurological surgery co-investigators.